Components of Upgradation Unit

Our containers and frames are designed with precision to house the biogas upgrading system. Each unit is equipped with two-stage membranes, a heat exchanger, and an efficient filtration system. This ensures optimal performance and longevity of the biogas upgrading process.

Key Features:

Two-stage membrane setup

Integrated heat exchanger

Advanced filtration system

Biogas Compressor(s)

The biogas compressors we offer are built to include all necessary safety features and are paired with an efficient oil filtration system. Operating within a working pressure range of 12 to 16 bar, these compressors ensure consistent and reliable performance.

Key Features:

Comprehensive safety features

Efficient oil filtration system

Operating pressure: 12 to 16 bar

Gas Conditioning Unit

Our gas conditioning unit features a Biogas Dryer Shell tube heat exchanger, designed to heat the biogas efficiently. Additionally, the unit includes refrigerating water chilling equipment to maintain the optimal temperature and enhance the overall efficiency of the biogas upgrading process.

Key Features:

Biogas Dryer Shell tube heat exchanger

Refrigerating water chilling equipment

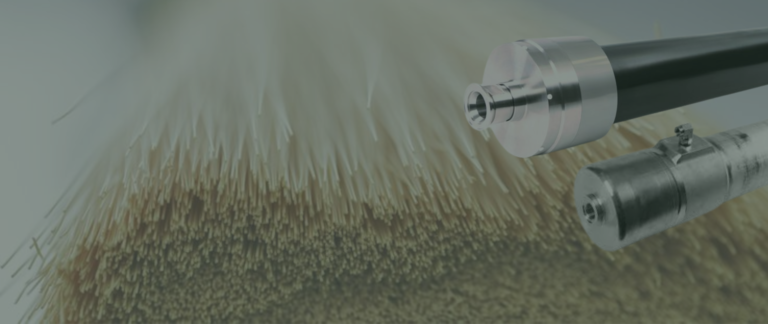

Filtration System

The filtration system in our biogas upgrading unit is designed to eliminate water vapors, oil, and other particulates from the raw biogas. It includes a coalescing filter, an oil absorber, and an activated carbon filter to ensure the highest level of purity and efficiency in the biogas produced.

Key Features:

Coalescing filter for water vapor elimination

Oil absorber for oil vapor removal

Activated carbon filter for particulate and oil vapor elimination

Micron dust removal filter